Quilting machine simple repair skills

Release Date: 2012/8/10 16:10:35 Total access[3574]TimesQuilting machine at work may find various problem, we also are incomplete, we simply introduce several common quilting machine fault repair, I hope everyone can help to.

In a quilting machine sewing thread loose surface line, float, material below the small coil pressing line plate bottom or the inner garbage; elastic line of spring elastic is too weak to nut, clean up the garbage; the thread take-up spring adjusting screw, the adjustment ring to pulling, increased elastic; the line inserts into clip.

The bottom line is a straight line, sewing materials showing below surface line line too tight or too coarse screw thread screwed spindle skin, exchange.

Di Xiansong bottom exposed material, surface line into linear bottom line too loose or too fine, the bottom line without shuttle skin or Suopinei garbage tightening spindle on the holster shuttle skin screws, will change into and surface line line line; fully wound bobbin to install or remove Suopinei garbage.

At the same time line loose sometimes surface line loose, sometimes line loose, elastic indefinite bobbin crooked or bobbin has rust; seam uneven thickness change round the bobbin in the bobbin, the surface of the sewing machine oil, and with coarse polish to rust; change the symmetry of the sutures.

Stitch stitch is not suitable for the aspects of needle distance screw too high or too low to adjust needle distance.

Stitch length is shorter when the presser foot is too low pressure regulating screw, increasing the pressure of the presser foot.

When sewing thin materials trace skew line is too thick to needle, wire and material matching table selection.

Material back there is a frame bit indications and wire drawing trace later printed, foot pressure too strong.

Change the new, reduce the pressure of the presser foot.

Material hand sewing the pieces do not move forward feeding tooth is too low to loosen teeth lift crank screw, raise the feeding teeth.

Sewing shrinkage bottom and surface line tightly, line too thick too hard, foot pressure tight exchange soft line, to alleviate the pressure of the pressure foot.

Sewing pieces of up and down feeding Ya Taigao lowered the feeding teeth.

The irregular oblique go feeding teeth transmission parts and screw loosening and tightening the feeding teeth drive screws.

To rotate with respect to rack loud rocker crankshaft and bearing of rocker bottom rocker ball loose, loose, pedal; the lower pulley screw loosening steel ring and Qu Zhoumo loss, ball off screwing rocker bent shaft at the top screw, screw bearing cap; the lower end of the rocker screw ring joint pedal on both sides of the square frame top screws; bolt tightening; replacement of steel ball and curved, and make up the ball.

Treading the fuselage vibration head did not put away, the frame is not flat, the foot edge screw loosening is placed the head frame, pad; the screw is screwed tightly.

With the parts after the discovery of rotating machines are heavy and big sound repair parts do not meet the requirements or improper assembly for another standard parts or repair parts to assembly amended.

The rotation is not flexible machine is not, be grease waste product note; belt tightly; the shuttle bed left inside the head, flannel, garbage all rotating parts with small amount of gasoline, treading machine for several minutes, then adding the sewing machine oil, the lubricating; remove the shuttle bed garbage removal.

When the rotation does not turn, sometimes on the wheel spin belt is too long, the clutch screw not tightened shorten or replace belt; clutch screw screw.

Head voice shuttle bed and send cloth teeth oil garbage; the shuttle bed is not installed; the rotation of screws were loose remove the shuttle bed, garbage removal; correction of the shuttle bed; tightening and loosening position correction section line when the most prone to breakage in line order wrong; thread did not put away or surface line too tight according to the wear surface line steps heavy wear; practice step machine hold towards their direction of rotation.

Dongguan City Hengye machinery limited company, is the first domestic production of computer multi-needle quilting machine manufacturers, set research and development, production and sales of quilting, mattress edge machine, sewing machine lines, cotton machines, sewing machines and other equipment for one. The main products are: computer quilting machine (computer shuttleless quilting, computer shuttle quilting machine), computer multi-head quilting embroidery machine, computer automatic cutting machine, Single-needle quilting machine,high speed bobbin winding machine mattress machine.Products are widely applied to: mattress fabrics, the summer was cooler, was the core, quilt cover, bedspread bedding, clothing and furniture, seating, fabric and sponge, chemical fiber cotton quilted fabric patterns, cutting.

News source: HengYeJiXie

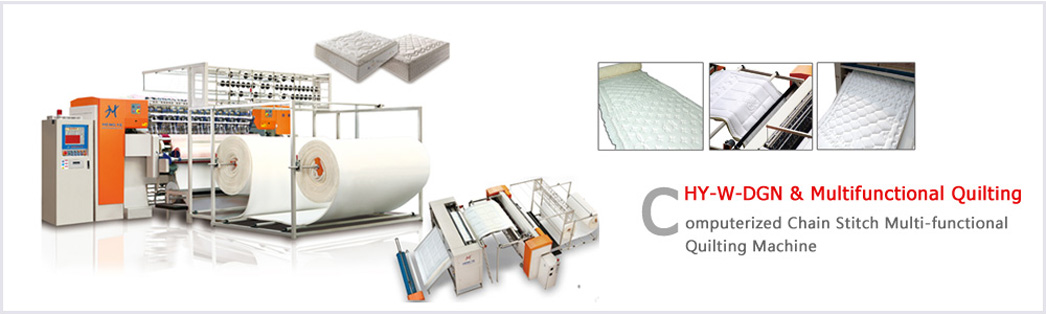

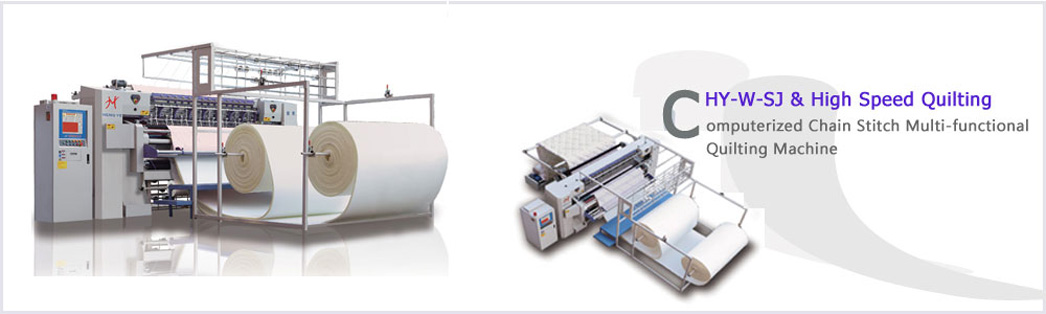

- Computerized Chain Stitch Multi-functional Quilting Machine

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

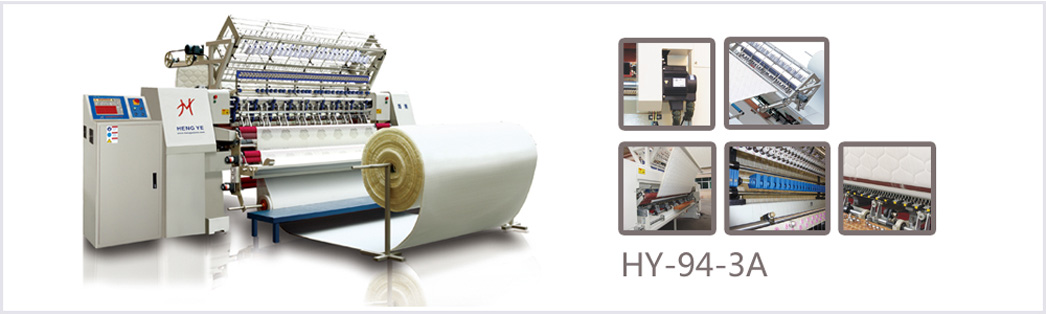

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

- Computerized Panel Cutter Machine

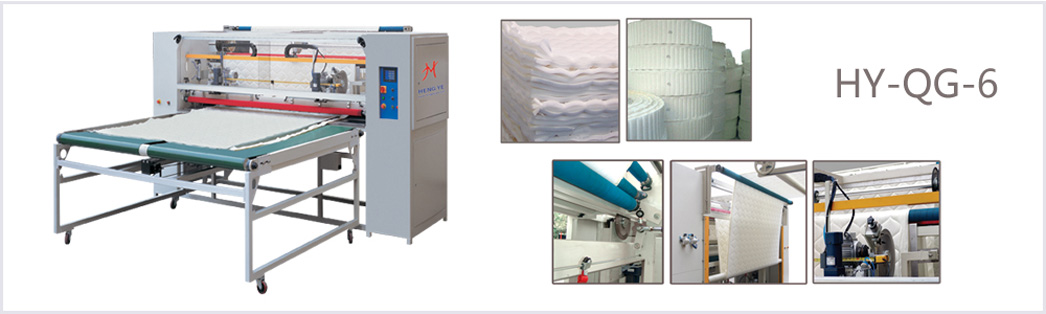

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français