Computerized quilting machine initial installation debugging (2)

Release Date: 2012/8/13 11:39:41 Total access[3458]TimesComputerized quilting machine initial installation debugging

ON "is set to ON, frequency converter according to the" speed 1 "" speed selected, select 2 "" speed 3 "state of operation; note: the observation of motor turning right or not, if not properly should be shut down, exchange motor U, V, W of arbitrary two.

The S1-S8 parameter is S1 to CD0 significance of parameter setting speed should be 0Hz S2 for the CD22 parameter setting speed according to the specific circumstances, to be adjusted, typically about 5Hz S3 for the CD23 parameter set the speed of V*2/7 S4 for the CD24 parameter set the speed of V*3/7 S5 for the CD47 parameter set the speed of V*4/7 S6 for the CD48 parameter setting V*5/7 S7 CD49 speed parameter setting velocity of V*6/7 S8 CD50 V V parameter setting speed for the spindle by use of the highest frequency of the spindle by use of the highest frequency is calculated to see software manual, the factory V value for the 50Hz, namely the value as set values: S1=0Hz S2=5Hz S3=14Hz S4=21Hz S5=28Hz S6=35Hz S7=42Hz S8=50Hz (more than parameter number specified ADLEEPOWER APxG3 series frequency converter, such as the use of other converters may set the parameter number is not the same as.;)

In debugging computerized quilting machinetime must pay attention: if the spindle frequency is not 50Hz, please before testing the transducer parameters according to the requirements set up, so as to avoid excessive lead to damage to the machine spindle speed.Can be a variety of combinations are trying again, to determine the correct wiring; enter "parameter setting" according to the specification of the software requirement calculation and setting of the parameters, return to the main screen;, shutdown, shut off the power supply is connected with the roller frame; electrical wiring; power on, starting up; manual rotating spindle so that the needle position signal feel; click on the main screen. "" key, saddle motor should move to the left, click on the main picture "" key, saddle motor should move right; click on the main screen of the "a" key, roller motor should move forward feed, click on the main screen "▼" key, Luo pull motor should be moved backward retreat cloth; if a motor to the contrary, the corresponding motor drive A+, A- switching; (should be in power for a simple graphics) optional, click "start" button, the machine should start working, press the "stop" button, the spindle speed and stopped on the needle. (high); adjustment of the needle position, is mainly to adjust the S1 set speed, the spindle motor can rotate in the case, the value of S1 as small as possible, with the other inverter parameter adjustment, mainIs to improve the inverter torque at low speeds, for the ADLEEPOWER APxG3 series inverter, can increase the CD21 (torsion) parameters.Press the "start" button "stop", observed for each dwell position, should be consistent, clutch voice should be small, if the stop position not pin high, should adjust needle retaining piece position, until the correct position; adjust the step (synchronous) escutcheon position, should be in the needle left cloth induction to the signal, usually in the needle high anterior 90 degrees; this basic debugging completed.

News source: HengYeJiXie

- Computerized Chain Stitch Multi-functional Quilting Machine

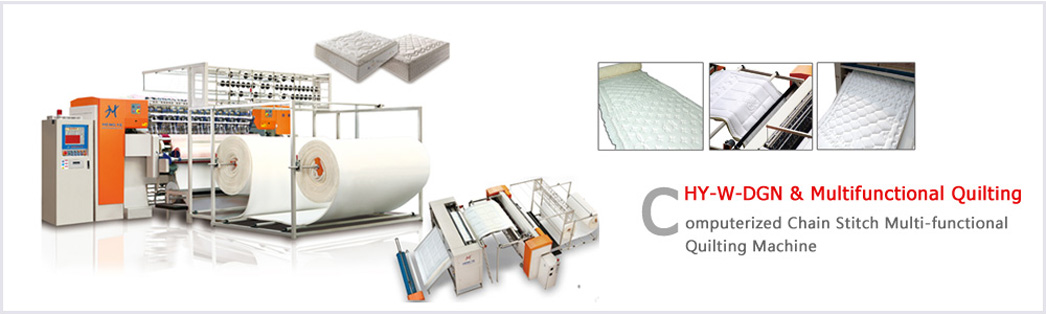

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

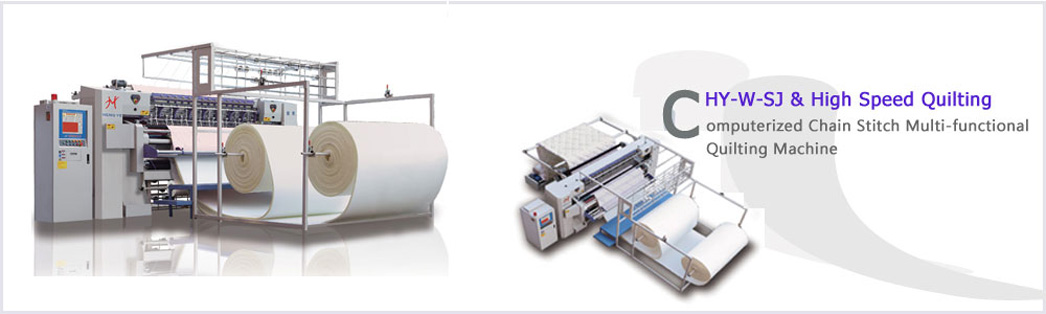

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

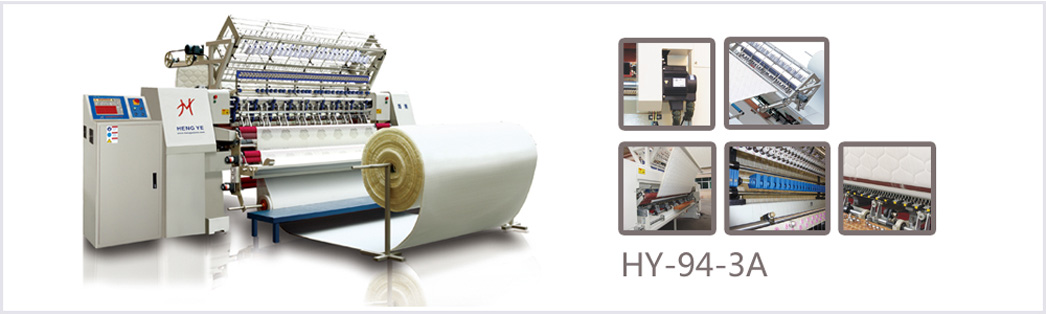

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

- Computerized Panel Cutter Machine

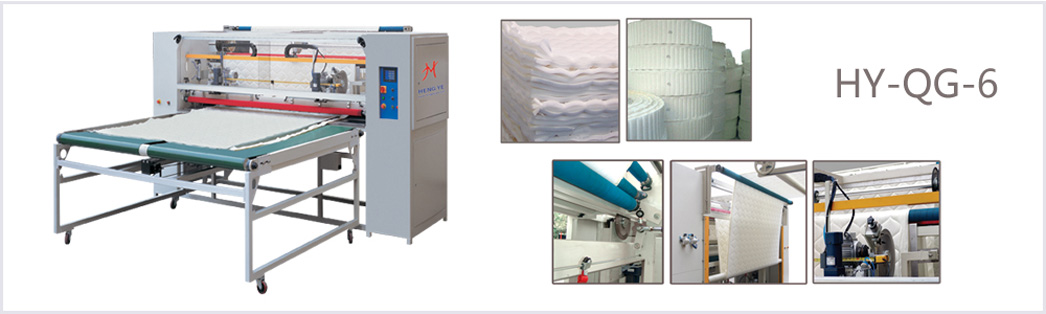

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français