Mattress machinery should pay attention to energy saving

Release Date: 2012/8/14 11:23:30 Total access[2995]TimesAlthough our mattress machinery manufacturing level to upgrade quickly, and with the international gap is narrowing, but foreign manufacturers to reduce costs, increase market share, in the Chinese localization of manufacturing process is being accelerated ceaselessly, and in China to establish operation mechanism, improve the rapid response capability and provides a full range of service solutions.International manufacturers have also begun to powerful alliances, such as Toyota Japan and Germany Trutzschler companies to strengthen cooperation, common development speed of up to 600 times per minute clamp combing machine, to high-end combing machine march.Therefore, China Textile machinery manufacturing industry should be formed as soon as possible intensive professional production, improve China"s equipment manufacturing industry"s core competitiveness, with more intense challenge.

In improving the automation, intelligent but also energy saving textile enterprises is the focus of attention, realization of machining process and energy saving of the mattress is one of the signs of advanced equipment.German textile machinery manufacturers in Germany mattress machinery and Equipment Manufacturing Industry Association launched the "focus on energy efficiency and environmental protection" sustainability initiatives and actions, "blue energy" is the equipment and engineering sustainable solutions international signs, "blue energy" concept of economic, environmental and social responsibility.

In this concept, the mattress machinery industry with intelligent technology to provide resource saving and managing efficiency of specific programmes, such as Trutzschler on each part of the machine set the standard of energy saving.Italy green label, used for identification of textile machinery energy and environmental performance.This is our country textile machinery should draw lessons from the concept, to avoid the emergence of mattress machinery manufacturers claim to energy-saving advanced equipment, but no real standards.Equipment energy saving from raising per unit area yield, improve product quality stability, application of electrical energy, the production process quality control system, automatic cleaning system and other point of view to achieve.However, energy saving is not only dependent on the equipment, but also depends on the correct method of using equipment.By comparison, RoCoS compact spinning device is the industry recognized power saving device, but according to experts, it is through the magnet ceramic accumulation for fiber strand accumulation, to use the premise is good attention to RoCoS compact spinning device installation and positioning, in order to achieve energy saving effect.Therefore, good equipment is able to play the greatest effectiveness, but also depends on the textile machinery manufacturers can provide customers with full service solutions. To optimize the structure design and the use of new materials and energy-saving measures.

More about the mattress machinery, or quilting machine related issues, please pay attention to our website information center.

News source: HengYeJiXie

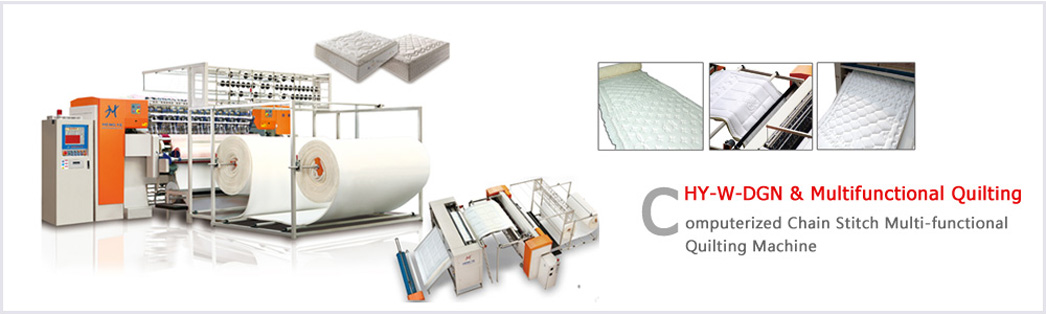

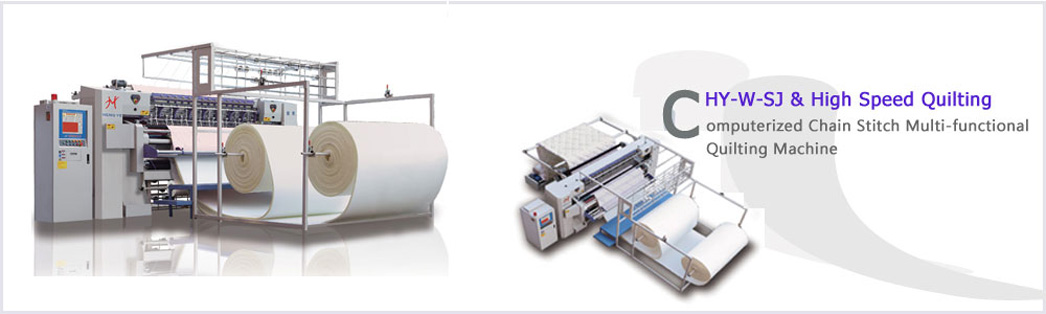

- Computerized Chain Stitch Multi-functional Quilting Machine

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-DGN )

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-SJ)

- Computerized Chain Stitch Multi-needle Quilting Machine【New】 (Model:HY-W-JH )

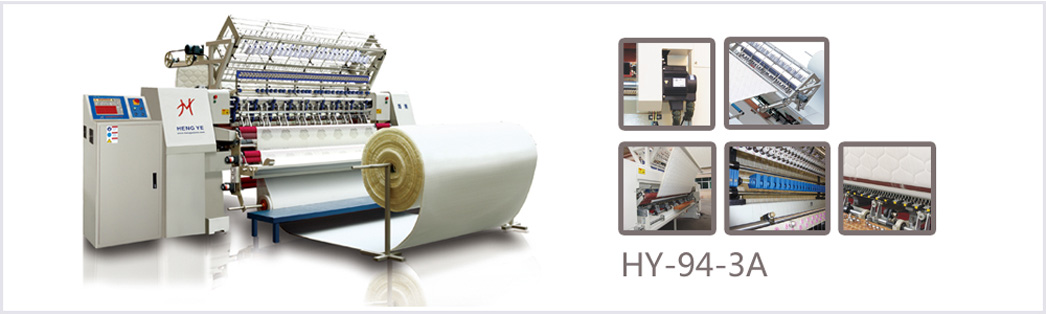

- Computerized Lock Stitch Multi-needle Quilting Machine

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-64-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Two Pin]【New】(Model:HY-94-2A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-64-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-94-3A)

- Computerized Lock Stitch Multi-needle Quilting Machine[Three Pin]【New】(Model:HY-128-3A)

- Computerized Quilting and Embroidery Machine

- Computerized Quilting and Embroidery Machine【New】(Model:HY-HX02-128)

- Computerized Panel Cutter Machine

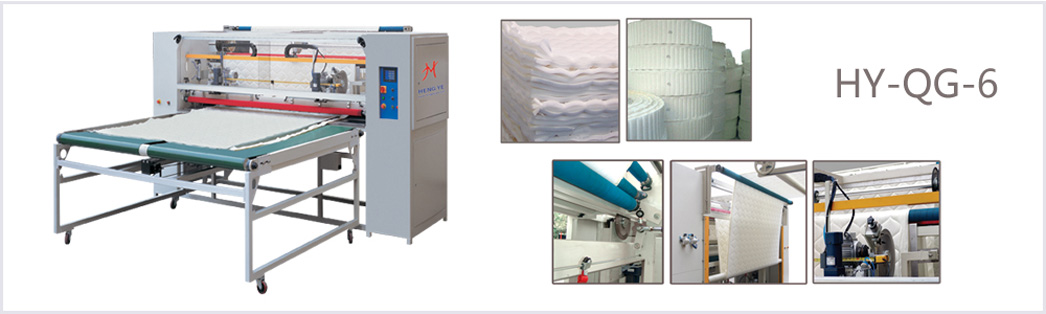

- Computerized Panel Cutter Machine【New】(Model:HY-QG-6)

- Computerized Panel Cutter Machine(Widen)【New】(Model:HY-QG-6L)

- Computerized Panel Cutter Machine(Model:HY-QG-3)

- Computerized Panel Cutter Machine(Model:HY-QG-2)

- Quilting Machine Accessories

- Bobbin Winder Machine(Model:)

- Knife Grinding Machine(Sharpen Machine)(Model:HY-MD-1)

- Material Roller Machine(Model:HY-JB-1)

- Material Roller Machine(Model:HY-JB-2)

中文简体

中文简体 English

English Español

Español العربية

العربية  Français

Français